Main Specifications

Vacuum contact materials SS316L stainless steel, tungsten, Kovar, glass

Measuring range 1.0×10-2~1.0×10+5Pa (air, N2, other gases require correction coefficients)

Measurement accuracy 2.0×10-2~1.0×10-1Pa: ±30%

1.0×10-1~1.0×10+4Pa: ±10%

1.0×10+4~1.0×10+5Pa: ±30%

Measurement repeatability 2.0×10-2~1.0×10-1Pa: 5%

1.0×10-1~1.0×10+3Pa: 2%

1.0×10+3~1.0×10+5Pa: 5%

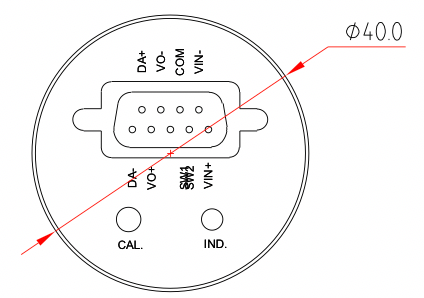

Display: Colored light strips indicate different vacuum levels, and various combinations of colors and display modes display the status of the vacuum gauge.

Data acquisition resolution 1%, response time <100ms

Temperature characteristics: working temperature 0 °C~+45°C, storage temperature -40 °C~+75°C

Probe baking temperature 180°C Max (without electronic control unit)

Maximum power consumption 1W Max

Power supply: recommended +24VDC (±20%)/0.5A, suitable for +5VDC~30VDC

Electrical signal interface RJ45 network interface (analog voltage, RS485, power input, control output)

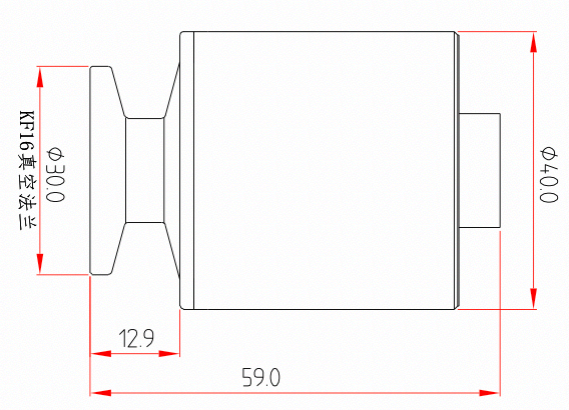

Vacuum chamber interface: DN16 ISO-KF (other options are optional), maximum pressure 1.5×10+5Pa

Weight 120 grams (including DN16 ISO-KF flange)

Features

• Vacuum measurement range covers 1E-2Pa to 1.0E+5Pa

• Colored light strips indicate different vacuum levels

• Intelligent reminder of vacuum gauge operating status and health status

• Intelligent calibration, automatic identification of atmospheric and high vacuum zero positions

•Supports automatic temperature compensation, wider applicable range

• Dual communication mode, standard data communication (Modbus), optional analog output (0-10V and 4-20mA)

• Highly compatible with international mainstream vacuum gauge brands, enabling seamless replacement

• Adapted to IVMS system to collect and record vacuum degree data in real time

• Small and exquisite body, special structural design enhances physical security performance

• Supports automatic fault clearance function and firmware upgrade function