Pumping speed :

18m³/hType :

TXG020Motor power :

1.1keProduct weight :

48kgAir cooling TXLG series dry screw vacuum pump

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, two screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.Dry Oil-Free Air Cooling Screw Vacuum Pump ,This is an advanced and widely used vacuum pump at present, It is one of the best-selling products of our company. It adopts explosion-proof motor with high configuration, It has the characteristics of low noise, no oil and pollution, clean and high vacuum, simple and convenient use, operation and maintenance, Widely used in many industries, For example, oil and gas recovery, vacuum coating, biomedicine, food processing, single crystal furnace, vacuum forming, vacuum melting, electronic photovoltaic, semiconductor synthesis and many other industries are used.The dry oil-free screw vacuum pump produced by our company is divided into air cooling and water cooling according to the extraction rate, and there are many models for you to choose

Our Advantages

here is no medium in the working chamber, which can obtain a clean vacuum.. No clearance between rotating parts, high speed operation, small overall volume.There is no compression in the gas, suitable for extraction of coagulable gas.Can remove a lot of steam and a small amount of dust gas occasions.. High vacuum, the ultimate vacuum up to 1 Pa.Screw material is high strength special material, material density, wear resistance, stable performance.No friction rotating parts, low noise.. Simple structure, convenient maintenance.Wider range of use: corrosive environment can be used.No oil consumption, no water.Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

Oil and gas recovery Biological medicine Food Processing

Single crystal furnace Vacuum formingVacuum flame refining

Electronic photovoltaic Semiconductor synthesis Biological products

Pharmaceutical process Chemical process

Solvent recovery Organic solvent recovery Medical instruments

Oil and gas recovery Thin film preparation

Biochemical testing analysis

microelectronics solar energy Material Handling

ADVANTAGES

Advanced technology, using advanced fifth generation composite screw technology;

Environmental protection - no oil, no water, no pollution, can obtain a clean vacuum, and the extracted materials can be recycled and reused; Energy saving, adopting variable pitch energy-saving technology, can reduce energy consumption by 30%;

Resistant to chemical corrosion, the pump chamber has a corrosion-resistant nano ceramic protective layer, and the O-ring is made of EPDM material, which is resistant to organic solvent corrosion;

Air cooled, adopting an air cooled structure, making it more convenient and simple to use; Save manpower, with maintenance cycles ranging from thousands to tens of thousands of hours;

High extreme vacuum, ≤ 1Pa, wide working area, continuous operation from extreme vacuum to atmospheric pressure;

Double ended mechanical seal, using the most advanced magnetic sealing device to make the seal more reliable, with smooth exhaust and good liquid handling ability;

Lightweight, using new lightweight materials, with a relatively light weight. Low noise, using high-precision machining parts, resulting in low noise;

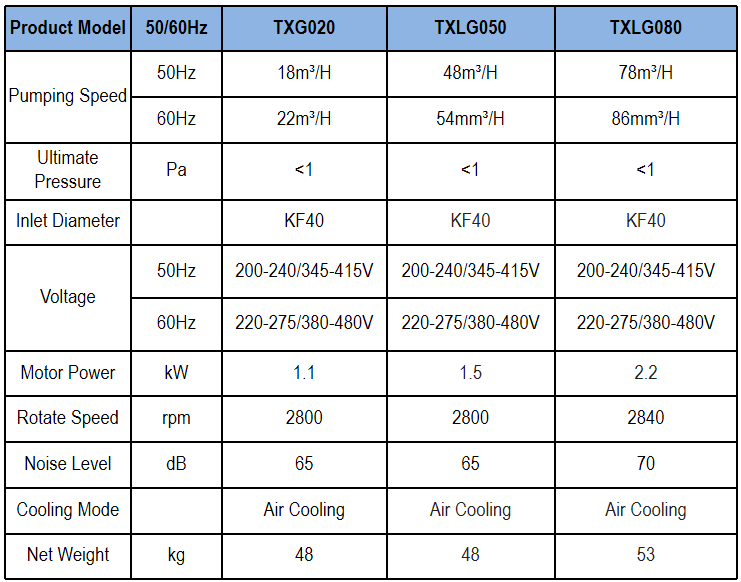

TECHNICAL SPECIFICATIONS

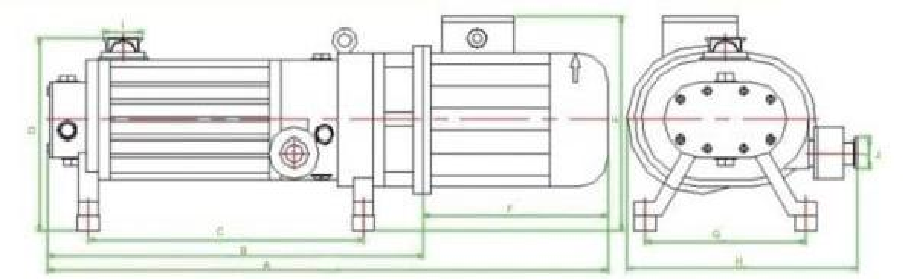

SIZE

|

Size and model |

Explosion proof motor |

Explosion proof motor |

B |

C |

D |

Explosion proof motor |

Explosion proof motor |

Explosion proof motor |

Explosion proof motor |

G |

H |

I |

J |

|

678 |

788 |

438 |

286 |

260 |

265 |

350 |

240 |

285 |

206 |

310 |

KF25 |

KF25 |

|

|

765 |

815 |

505 |

330 |

270 |

290 |

365 |

260 |

310 |

220 |

316 |

KF40 |

KF25 |

|

|

840 |

885 |

560 |

385 |

270 |

290 |

365 |

280 |

325 |

200 |

316 |

KF40 |

KF25 |

Tags :