Pumping speed :

165 to 500 m3/hType :

2BV6110, 2BV6111, 2BV6121, 2BV6131, 2BV6161Limit vacuum :

3300 paPumping volume: 165 to 500 m3/h

Ultimate vacuum: 3300 pa

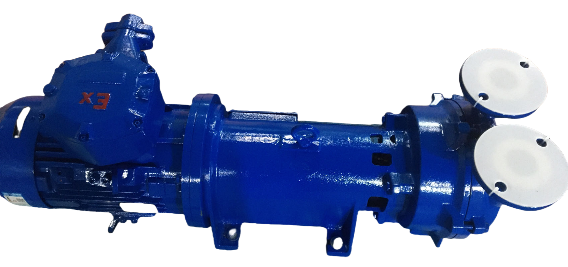

Water Ring Vacuum Pumps and Compressors – Compact and Efficient Solutions

Product model: 2BV6110, 2BV6111, 2BV6121, 2BV6131, 2BV6161

2BV6 series vacuum pump description: explosion-proof motor, direct drive, bracket structure connection.

Standard configuration: explosion-proof motor, imported mechanical seal and bearing; SS304 stainless steel material.

Product application: mostly used in the chemical industry, explosion-proof working environment or high corrosion working environment, so there are many choices for the pump head material, namely: standard cast iron material, full pump stainless steel 304, full pump stainless steel 316L, etc.

2BV series liquid ring vacuum pump is suitable for inhaling gas and steam, and the suction pressure can reach 33mbar (absolute) (i.e. 97% vacuum degree). When the liquid ring vacuum pump works for a long time under the condition that the suction pressure is close to the ultimate vacuum (saturated pressure of the working liquid), it should be matched with a cavitation protection tube to protect the pump. When used as a compressor, the maximum pressure is 0.26mpa (ABS). As a new generation of energy-saving products, the 2BV series liquid ring vacuum pump will completely replace the SK and 2SK series liquid ring vacuum pumps and the W, WY, WL series reciprocating vacuum pumps with its superior performance and advantages.

The 2BV6 series liquid ring vacuum pumps and compressors are mainly used to pump explosive gases or work in flammable and explosive environments. The technical parameters of each type are the same as the corresponding types of 2BV2 and 2BV5 series products.

Features

High reliability

Easy maintenance

Mechanical seal is used as standard configuration

Oil-free design is conducive to environmental protection

Smooth operation, noise can be as low as 62 decibels

With self-priming function, easy to operate

Uniform corrosion-resistant design

Can be used to form vacuum or generate pressure

Reliable quality, manufactured in accordance with ISO9001 standards

Direct coupling design, easy installation, saving space.

The pump has a cavitation protection port open (or connected to the separator) to ensure maximum suction, eliminate cavitation noise, and protect the pump

The entire 2BV series uses aluminum bronze impellers with high strength to improve its corrosion resistance and durability. If the liquid flow parts are made of stainless steel, the pump can work under harder conditions.

Technical Data

|

Pump Model |

Rated Power |

Capacity |

Working fluid flow |

weight |

noise |

|

|

(KW) |

(m3/h) |

(m3/h) |

(kg) |

dB(A) |

|

2BV6110 |

4 |

165 |

0.8 |

145 |

63 |

|

2BV6111 |

5.5 |

230 |

1 |

197 |

68 |

|

2BV6121 |

7.5 |

280 |

1.2 |

221 |

69 |

|

2BV6131 |

11 |

400 |

1.8 |

303 |

73 |

|

2BV6161 |

15 |

500 |

2.4 |

439 |

74 |

|

model |

Maximum suction Force Capacity m3/h |

Entrance and Exit mouth |

Water inlet |

Motor power kW 50Hz |

Engine explosion proof grade |

Pump, speed Speed, speed |

Management LiquidFlow rate L/min bell |

|

2BV6-060 |

27 |

G1 |

G3/8 inch |

2P-1.1kW |

|

2840 |

2.5 |

|

2BV6-061 |

52 |

G1 |

G3/8 inch |

2P-1.5kW |

|

2840 |

2.5 |

|

2BV6-070 |

80 |

G1.5 inch |

G3/8 inch |

2P-3kW |

|

2860 |

3 |

|

2BV6-071 |

110 |

G1.5 inch |

G3/8 inch |

2P-4kW |

|

2880 |

4.7 |

|

2BV6-110 |

165 |

DN50 type |

G1/2 inch |

4P-4kW |

|

1440 |

6.7 |

|

2BV6-111 |

230 |

DN50 type |

G1/2 inch |

4P-5.5kW |

Explosion- proof |

1440 |

10 |

|

2BV6-121 |

280 |

DN65 type |

G3/4 inch |

4P-7.5kW |

DIIBT4/ DIICT4 type |

1440 |

12 |

|

2BV6-131 |

400 |

DN65 type |

G3/4 inch |

4P-11kW |

|

1460 |

17 |

|

2BV6-161 |

500 |

DN80 type |

G3/4 inch |

6P-15kW |

|

970 |

23 |

| Industrial Vacuum Systems |

| Vacuum Pumping Technology |

| Liquid Ring Vacuum Pump Applications |

| Industrial Liquid Ring Pumping Solutions |

| Environmental Friendly Vacuum Pump |

| Corrosion Resistant Liquid Ring Pump |

| Robust Construction Liquid Ring Pump |

| Reliable Liquid Ring Pump Operation |

| Low Vibration Liquid Ring Pump |

| Noise-Free Liquid Ring Vacuum Pump |

| Liquid Ring Pumping Solutions |

| Efficient Liquid Ring Vacuum Pump |

| Positive Displacement Liquid Ring Pump |

| Oil-Free Liquid Ring Vacuum Pump |

| Customizable Liquid Ring Vacuum Pump Solutions |

| Liquid Ring Pump System Integration |

| Energy-Efficient Vacuum Pump |

| Liquid Ring Pump Efficiency |

| Liquid Ring Pumping Technology |

| Industrial Liquid Ring Pump Suppliers |

| Liquid Ring Pumping Systems |

| Liquid Ring Pump Industry |

| Liquid Ring Pump Manufacturers |

| Dry Liquid Ring Vacuum Technology |

| Environmental Liquid Ring Pump Solutions |

| Liquid Ring Pumping Technology Innovations |

| Industrial Vacuum Solutions |

| Liquid Ring Vacuum Pump Components |

| Vacuum System Integration |

| Efficient Vacuum Process Technology |

| Liquid Ring Vacuum Pump Market Trends |

| Dry Liquid Ring Vacuum Pump Suppliers |

| Liquid Ring Pumping Industry |

| Low Maintenance Industrial Vacuum Pump |

| High Efficiency Liquid Ring Vacuum Pump Technology |

| Liquid Ring Pump for Chemical Processing |

| Liquid Ring Vacuum Pump for Food Processing |

| Liquid Ring Pump for Pharmaceutical Manufacturing |

| Liquid Ring Pump for Environmental Technology |

| Liquid Ring Vacuum Pump for Plastics Industry |

| Liquid Ring Pump for Paper and Printing |

| Liquid Ring Pump for HVAC Systems |

| Liquid Ring Pump for Water Treatment |

| Liquid Ring Vacuum Pump for Pneumatic Conveying |

| Liquid Ring Pump for Distillation Processes |

| Liquid Ring Pump for Semiconductor Manufacturing |

| Liquid Ring Vacuum Pump for Solar Panel Manufacturing |

| Liquid Ring Pump for Composite Materials |

| Liquid Ring Pump for Cryopumps and Cryogenic Systems |

| Liquid Ring Pump for Vacuum Insulation Panels |

| Liquid Ring Pump for Aerospace Testing |

| Liquid Ring Vacuum Pump for Automotive Industry |

| Liquid Ring Pump for Electronics Manufacturing |

| Liquid Ring Pump for Oil and Gas Processing |

| Liquid Ring Vacuum Pump for Industrial Deaeration |

| Liquid Ring Pump for Plastic Extrusion |

| Liquid Ring Pump for CNC Router Vacuum Tables |

| Liquid Ring Vacuum Pump for Woodworking |

Dimensional appearance

2BV6 Series Water Ring Vacuum Pumps and Compressors – High-Efficiency Industrial Solutions

The 2BV5 series water ring vacuum pumps and compressors are designed for demanding industrial applications, offering energy-efficient, low-maintenance solutions for handling wet and vapor-laden gases. With robust construction and reliable performance, these systems are ideal for continuous operation in various sectors.

·

Key Features:

·

o High efficiency: Reduces energy consumption while ensuring optimal performance.

o Durable design: Built for long-term use in harsh industrial environments.

o Wet gas compatibility: Effectively handles vapor-laden and moisture-rich gases.

o Low maintenance: Simplifies operation and minimizes downtime.

o Versatile applications: Suitable for both vacuum and compression tasks.

Applications:

o Chemical industries: Gas recovery and vapor handling for process optimization.

o Power generation: Vacuum and compression systems for turbines and condensers.

o Food and beverage production: Clean vacuum solutions for hygienic processing.

o Environmental systems: Effective for wastewater treatment and gas handling.

o General industrial use: Reliable for forming, drying, and coating applications.

The image should showcase the pump in an industrial setting, such as a chemical plant or manufacturing facility. Highlight its robust features with visual aids or icons emphasizing energy efficiency, durability, and low-maintenance operation.

Tags :