Features

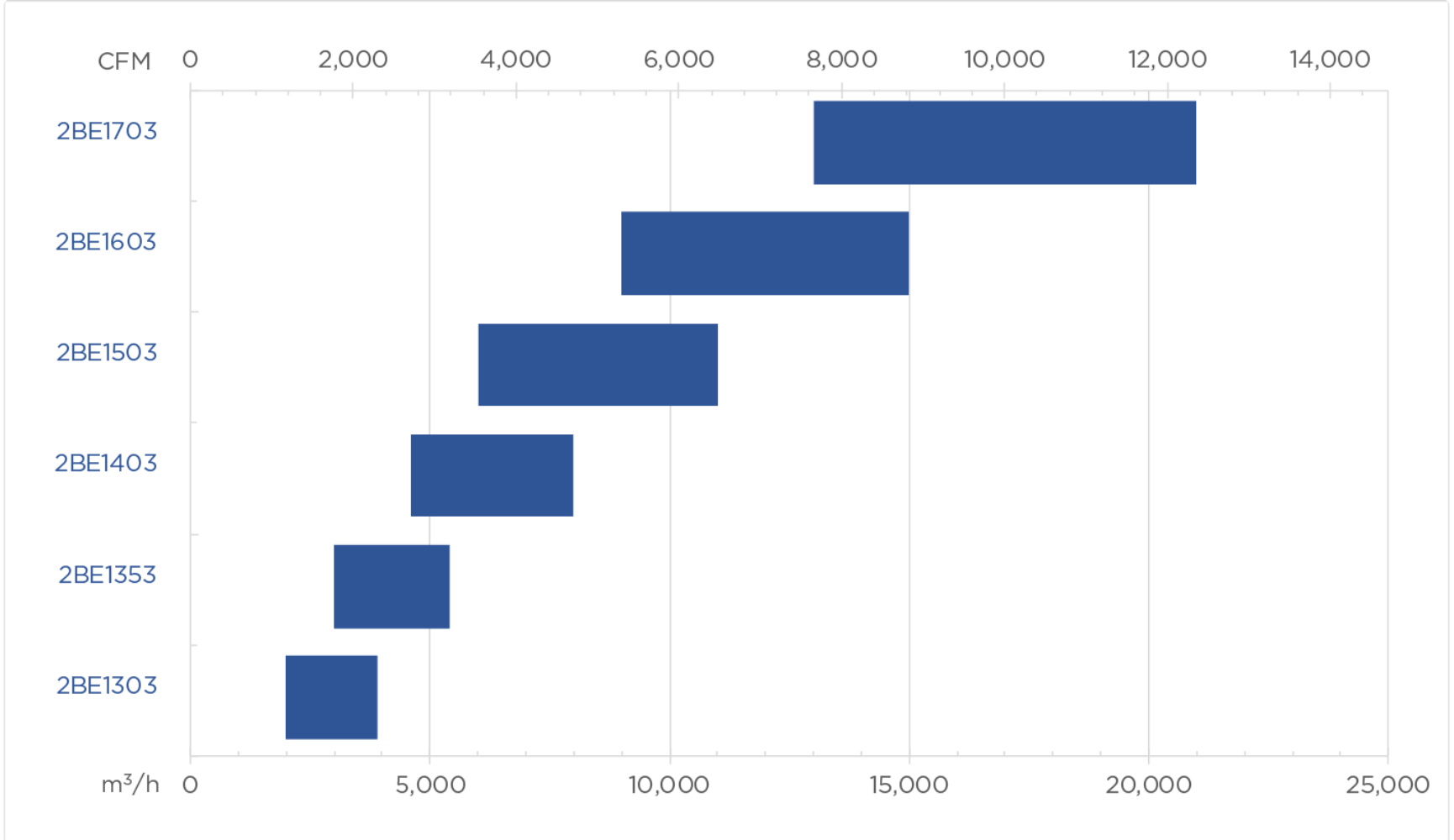

• Broad Capacity Range: Available in 23 models, the 2BE1 series accommodates a wide range of capacity requirements.

• High-Pressure Capability: Operates with a discharge pressure range up to 50 psia (3.5 bar abs), suitable for demanding applications.

• Versatile Material Options: Offered in cast iron, stainless steel, and combined materials for enhanced durability, including applications involving corrosive gases or liquids.

• Single-Unit Vacuum and Compression: Enables simultaneous vacuum and compression in one pump, eliminating the need for separate equipment and simplifying installation.

• Low Maintenance: The 2BE1 series is designed as a single-stage pump with straightforward maintenance and high energy efficiency.

• Efficient Discharge System: Features unique PTFE (polytetrafluoroethylene) valve plates that adjust to the intake pressure, optimizing energy use and preventing excessive compression.

• Rugged Design: The impeller and pump shaft are constructed for strength and stability, with blades that undergo heat-treated welding to resist impact and bending, making the pump suitable for harsh working environments.

Product Details

Key components like the impeller, pump shaft, and distribution plate are engineered for efficiency and energy savings. Impeller blades are precisely stamped in one step during the welding process, ensuring balance and durability. The impeller and pump shaft are joined with a shrink-fit connection, providing a stable, reliable operation. Each pump features a built-in air-water separator with multiple exhaust ports, simplifying vacuum system connections. Additionally, an inspection window on the pump cover allows for easy adjustments to the shaft packing and impeller.

Technical Data

|

Capacity |

47-930 scfm |

80-1580 Nm3/h |

|

Exhaust pressure |

35 psig |

3.5 bar abs. |

|

Industry |

Chemical, petrochemical, general industry |

|

|

Applications |

Reaction process, VCM recovery, explosive gas compression, filtration, solvent recovery, carolingian vapor recovery |

|

Applications

The 2BE1 Liquid Ring Vacuum Pump Series is ideal for applications in:

• Chemical and Petrochemical: For handling corrosive gases or liquids, often in processes requiring vacuum or compression.

• Pulp and Paper: Suitable for removing air from sealed containers and maintaining vacuum in paper production.

• Power Generation: Used to support power plant operations, such as gas handling and maintaining pressure.

• Industrial Processing: Widely used across industries like pharmaceuticals, instrumentation, metallurgy, construction, electronics, coal washing, mineral concentration, and fertilizer production, especially when high vacuum and reliability are essential.

Tags :