Pumping speed :

30m3/HHelium mass spectrometer leak detector is a high-precision detection device, mainly used to detect small leaks in vacuum systems and equipment. The device determines the integrity of the sealing system by detecting helium leaks, and is a key tool in industries such as aerospace, semiconductors, and electronic manufacturing. TaiXing 's helium mass spectrometer leak detector series products are widely used in various vacuum leak detections due to their high sensitivity and fast response.

Product advantages:

· Efficient and reliable performance : Built-in test leak source and high-quality mass spectrometer to ensure high accuracy and stability

· High sensitivity, capable of detecting extremely low helium leak rates

· Low cost of ownership : reliable design, low energy consumption, long maintenance intervals, few parts replacements , and long ion source life

· Mobile solution : quick start, ready to use in 2 minutes , large clear graphic display, direct access to key functions , lightweight design, easy to move

· Customizable for any application : Flexible remote control options including color touch screen, local graphic display, audible leak detection indication , etc. , with partial flow kit for effective vacuuming , multiple leak detection lines, precise leak location

· High stability and precision

1. High sensitivity : Able to detect minimum leak rates as low as 5.0E-13 Pa.m³/s, ensuring detection accuracy.

2. Fast response : The device response time is less than 0.5 seconds, and leakage data can be quickly obtained.

3. Multi-gas detection : supports the detection of multiple gases such as He4, He3 and H2, meeting various detection needs.

4. Multi-language support : The operation interface supports Chinese, English, and Russian, which is convenient for international users.

5. Rich communication interfaces : Equipped with RS232 and IO interfaces, supporting a variety of data transmission and device connection methods.

|

model |

TX400H |

TX280H |

TX280S |

|||||

|

Minimum detectable leak rate He4 |

5.0E-13Pa.m3/s (vacuum) |

≤ 5.0E-9Pa.m3/s (inhalation) |

5.0E-13Pa.m3/s (vacuum) |

≤ 5.0E-9Pa.m3/s (inhalation) |

5.0E-13Pa.m3/s (vacuum) |

≤ 5.0E-9Pa.m3/s (inhalation) |

||

|

Response time |

≤ 0.5 seconds |

≤ 0.5 seconds |

≤ 0.5 seconds |

|||||

|

Start Time |

≤3 minutes |

≤3 minutes |

≤3 minutes |

|||||

|

Molecular pump pumping speed He |

2.5L / s ( Hicube 80) |

2.5L / s ( Hicube 80) |

2.5L / s ( Hicube 80) |

|||||

|

Backing vacuum pump pumping speed

|

Oil-free scroll vacuum pump

|

8L/s;(Iwata 500C/ Agilent TS600);30m³/h |

Oil-free scroll vacuum pump

|

8L/s;(Iwata 500C/ Agilent TS600);30m³/h |

|

|||

|

4L/s;(Iwata 250C/ Agilent TS300);15m³/h |

4L/s;(Iwata 250C/ Agilent TS300);15m³/h |

|||||||

|

Oil type rotary vane vacuum pump |

6L/s;( TX224 , etc. ) ; 24 m³/h |

Oil type rotary vane vacuum pump |

6L/s;( TX224 , etc. ) ; 24 m³/h |

Built-in oil-type rotary vane vacuum pump : 0.5 L/s; GHD031B; 1.8 m³/h |

||||

|

Detectable gas |

Helium 4/ Helium 3/ Hydrogen |

Helium 4/ Helium 3/ Hydrogen |

Helium 4/ Helium 3/ Hydrogen |

|||||

|

Units of measurement |

Pa.m3/s , mbar.l/s , Torr.l/s , PPm |

Pa.m3/s , mbar.l/s , Torr.l/s , PPm |

Pa.m3/s , mbar.l/s , Torr.l/s , PPm |

|||||

|

source of ion |

Yttrium oxide iridium wire (two pieces) |

Yttrium oxide iridium wire (two pieces) |

Yttrium oxide iridium wire (two pieces) |

|||||

|

Mass spectrometry room |

180° Inhomogeneous Magnetic Deflection Mass Spectrometry |

180° Inhomogeneous Magnetic Deflection Mass Spectrometry |

180° Inhomogeneous Magnetic Deflection Mass Spectrometry |

|||||

|

Calibrated leak |

Channel type -7mbar.l/s (built-in leak) |

Channel type -7mbar.l/s (built-in leak) |

Channel type -7mbar.l/s (built-in leak) |

|||||

|

Communication Interface |

RS232/ Input and Output |

RS232/ Input and Output |

RS232/ Input and Output |

|||||

|

language |

Chinese / English / Russian |

Chinese / English / Russian |

Chinese / English / Russian |

|||||

|

working environment |

Temperature 5~40℃ Humidity ≤80% |

Temperature 5~40℃ Humidity ≤80% |

Temperature 5~40℃ Humidity ≤80% |

|||||

|

Power supply |

AC220V±10 |

AC220V±10 |

AC220V±10 |

|||||

|

weight |

About 115 Kg |

About 98 Kg |

About 40 Kg |

|||||

|

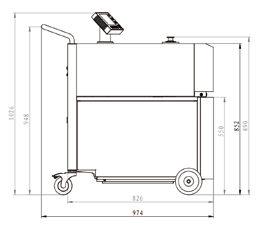

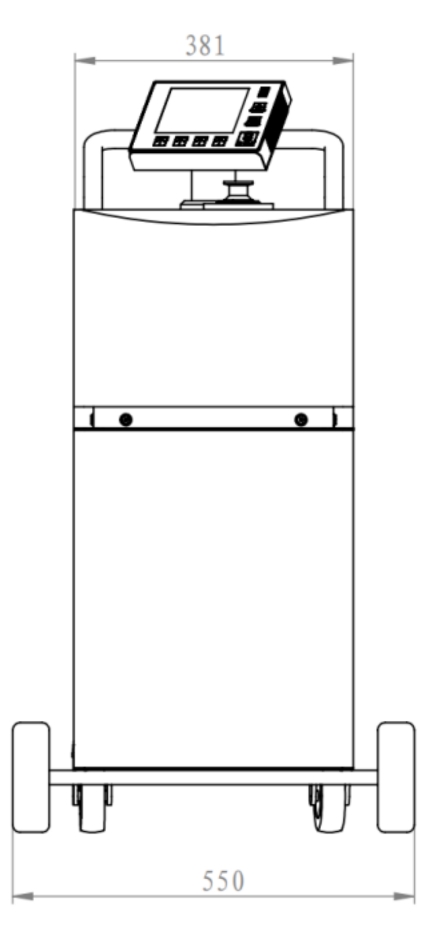

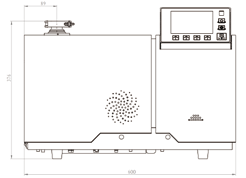

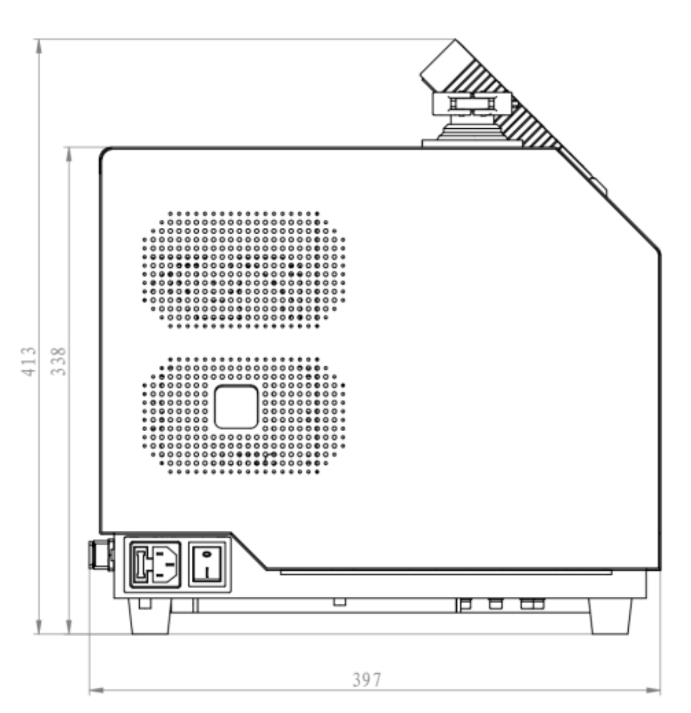

size |

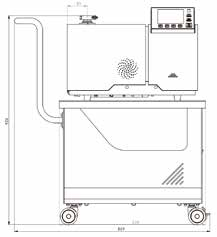

974mm * 550mm * 1026mm |

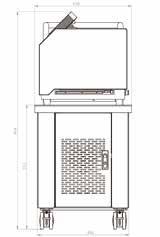

869mm * 406mm * 926mm |

600mm * 397mm * 376mm |

|||||

· The TX 400 was born to meet the standards for dry helium testing in the vacuum industry and semiconductor manufacturing.

· A high-speed leakage detector with additional gas line auxiliary pumping. Better shortened pumping time and faster response time

· Added inlet calculation and internal calculation, after calculation, it can continue the helium inspection work when the helium in the detection environment is high

· The detection limit reaches 1.0E-12mbar·l/s, entering the advanced ranks

· Equipped with a wireless remote control, it can better detect and control the equipment smoothly at a straight line distance of more than 100m (obstacle-free)

· Use TX series APP to connect to remote control device via Bluetooth (barrier-free 50m)

· Six different application setup guides are provided to help users properly configure the instrument for optimal performance.

· The touch screen rotates 180 degrees for easy viewing by users . The advanced 180° non-uniform magnetic deflection mass spectrometry technology, combined with the yttrium oxide iridium wire ion source, ensures high accuracy and stability of detection .

· Advanced charting capabilities include zoomed-in data, color-coded set points, and more.

TaiXing HLD offers oil-free scroll vacuum pumps and rotary vane pump options in different configurations to meet various application needs, such as large vacuum systems, scientific research, automotive component testing, etc.

· TX 400 model : Equipped with a 2.5 L/s molecular pump and an 8 L/s oil-free scroll vacuum pump for the fore stage (or a 6 L/s oil-free rotary vane vacuum pump ), it is suitable for high-precision detection needs.

· TX 280 S model : Portable design, built-in 0.5 L/s oil-operated rotary vane vacuum pump , suitable for on-site inspection.

· TX 280H model : cart-type design, supports high pumping speed detection, and flexible configuration.

| Aerospace Leak Testing |

| Automotive Leak Detection |

| HVAC System Leak Testing |

| Medical Device Leak Testing |

| Refrigeration System Leak Detection |

| Semiconductor Manufacturing |

| Power Plant Leak Detection |

| Vacuum System Integrity Testing |

| Pharmaceutical Industry Leak Testing |

| Oil and Gas Industry Leak Detection |

| Electronics Manufacturing Leak Testing |

| Research Laboratory Vacuum Systems |

| Food Packaging Industry Leak Detection |

| Environmental Chamber Leak Testing |

| Industrial Equipment Leak Testing |

| Plumbing System Leak Detection |

| Automated Production Line Leak Testing |

| Vacuum Furnace Leak Detection |

| Solar Panel Manufacturing Leak Testing |

| Battery Manufacturing Leak Detection |

Helium mass spectrometer leak detectors are widely used in the following fields:

· Semiconductor and electronics manufacturing : Testing the airtightness of chips and electronic components.

· Aerospace : Used for vacuum leak detection in spacecraft and aviation equipment.

· Pharmaceuticals and Chemicals : Ensure that the production environment of pharmaceuticals and chemicals is leak-free.

· Automobile manufacturing : Testing the air tightness of automobile parts, such as airbags and brake systems.

· Analytical instruments: electron microscope, leakage detection, mass spectrometry, surface analysis, etc.

· Research and development: space simulation, cryogenic research, nanotechnology, coating systems, etc.

· Semiconductor: load lock, transfer, metrology, lithography, physical vapor deposition (PVD), plasma etching, implantation source, chemical vapor deposition (CVD), flat panel display, LED, etc.

· Industry: industrial leakage detection, electron beam welding, lamp tube manufacturing, glass coating, brake pipe and air conditioning, refrigeration system manufacturing, heat treatment, power, vacuum furnace, etc.

· High energy physics: beam, accelerator, fusion, laser evacuation, etc.

1. Wireless remote control : supports barrier-free transmission within 100 meters, convenient for remote operation.

2. Intelligent suction gun : the length can be customized, with remote zeroing and alarm prompt functions.

3. Semi-automatic leak detection box : suitable for helium pressure detection of semiconductor chips.

4. Adjustable helium spray gun : two types are available: flow-controlled and fixed flow, to meet different application requirements.

Tags :