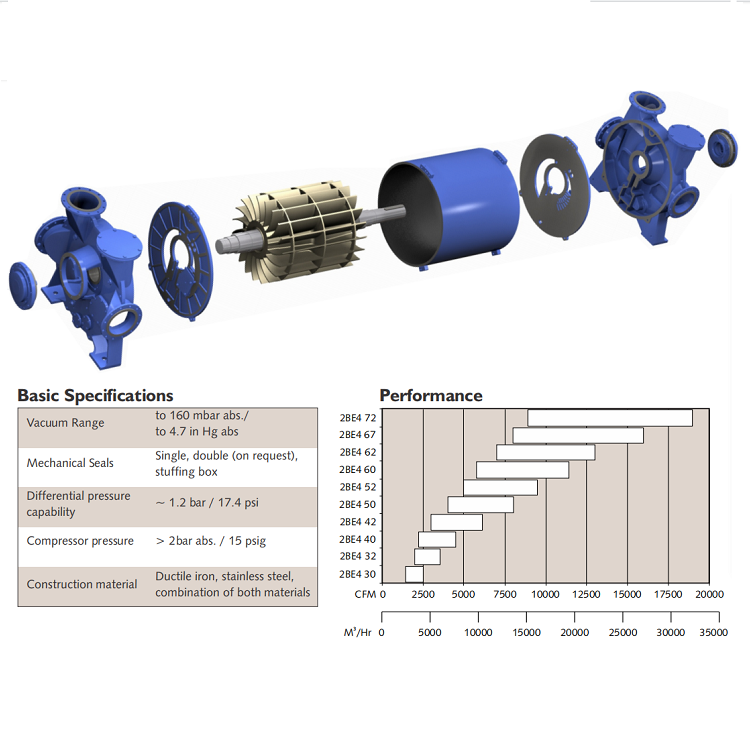

Type :

2BE4The 2BE4 pump operates efficiently over the entire vacuum range without changing the pump internals. When equipped with a center shroud, it can be used in two applications with a difference of up to 12 inHg (400 millibar). This has obvious advantages as it reduces the number of vacuum pumps used, saving space and installation costs.

flat disc liquid ring vacuum pump/compressor designs have been supplied to thousands of plants around the world, providing proven performance, reliability and peace of mind. With continuous innovation, our designs feature:

l The discs feature variable porting so the pump performance is optimized over the entire operating range.

l Large pressure difference capability

l High tolerance to liquid residues

l Large inspection port for easy internal inspection

l When closed, the orifice allows the pump to be completely drained

The capacity range of this series is 1500 to 19000 cubic feet per minute (2500 to 33000 cubic meters per hour). This is achieved by modifying the shaft bearings and optimizing the port plate and impeller. The improvement of internal flow channels has reduced energy requirements by 6% to 8%. The optimization of shaft bearings improves the flexibility of pump operation in case of malfunctions, ensuring better lubrication and extending service life. Optional connections for flushing the casing are also provided. This feature improves cleanliness and lifespan.

Some applications require both vacuum and compression in one process. Our liquid ring vacuum pumps and compressors can handle the gas in one pump instead of two separate machines - reducing costs and simplifying installation.

The unique inlet configuration allows for top and side inlet placement to accommodate low headroom installations. In installations where space is limited, the 2BE4 can be top mounted with the discharge separator, saving floor space and eliminating the need for trenches. The 2BE4 pump is very quiet during operation. Even with the larger pumps, sound levels are recorded at only 72 to 85 dB(A) measured at 3.3 feet (1 meter) from the source.

Designed to operate in demanding environments such as the paper, power, mining, sugar and chemical processing industries, these pumps offer durability and reliability at low operating costs. The standard polyisoprene lining on the pump body provides excellent corrosion resistance against aggressive process gases and liquids. The polyisoprene lining also consumes less energy than an equivalent unlined pump. For added corrosion resistance, some models feature stainless steel internal components.

2BE4 Large Capacity Liquid Ring Vacuum Pump – High-Performance Industrial Solution

The 2BE4 vacuum pump is designed for industrial processes that require high suction volumes and reliable performance in demanding environments. As a robust and energy-efficient water ring vacuum pump, the 2BE4 is suitable for handling wet gases and moisture-laden processes while offering low maintenance and long-lasting durability.

Key Features:

o Large capacity performance: Handles heavy-duty industrial applications with ease.

o Energy efficiency: Reduces power consumption without compromising reliability.

o Moisture and wet gas handling: Effectively manages processes involving moisture-laden gases.

o Durable design: Built for long-term operation in harsh industrial conditions.

o Low maintenance: Simplifies upkeep, minimizing downtime and costs.

Applications:

o Chemical industry: Efficient gas recovery, vapor handling, and moisture removal.

o Power generation: Vacuum systems for turbine exhaust and condensers.

o Environmental solutions: Wastewater treatment and vapor management processes.

o Pulp and paper manufacturing: Moisture control and vacuum-assisted drying.

o General industrial use: Suitable for forming, drying, and coating operations.

Advantages:

o High suction capacity for large-scale operations.

o Reliable performance in heavy-duty applications.

o Energy-efficient operation for reduced costs.

The image should feature the pump in a professional industrial setup, such as a chemical plant or power generation facility. Use labels or icons to highlight its large capacity, energy efficiency, and suitability for moisture-rich processes.

Tags :