Type :

AT706/AT1006/TC11/AT2006/AT3006

Advantages:

1. Multiple installation points; Driven by a belt-style elastic coupling.

2. The shield on the impeller blade makes it highly wear-resistant and corrosion-resistant, stable and reliable.

3. The sealing type can be equipped with different industries, such as packing seals, single-ended or double-ended (cartridge type) mechanical seals.

4. Materials are optional to meet the harsh working environment, such as carbon steel, stainless steel, duplex stainless steel, titanium, etc.

5. Double-stage design, small compression ratio, small temperature rise in high vacuum area, effectively preventing cavitation.

Applications:

AT/TC series conical double-stage water ring vacuum pump is equipped with international brand motors, heat exchangers, valves, automatic control instruments, etc., which integrates a safe, efficient and automatic operation vacuum system. It is widely used in power plant condenser vacuum, as well as drying, evaporation, distillation, concentration, filtration, dehydration, degassing and other industries in food, pharmaceutical, chemical, paper and other industries.

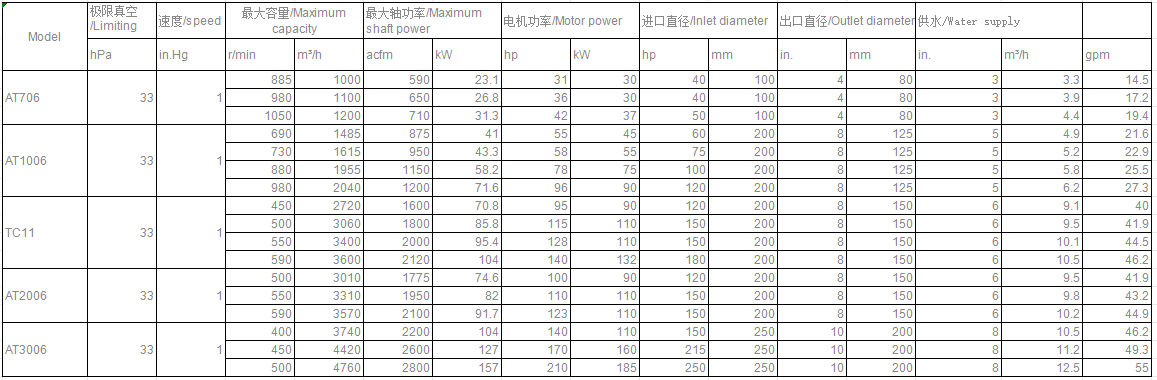

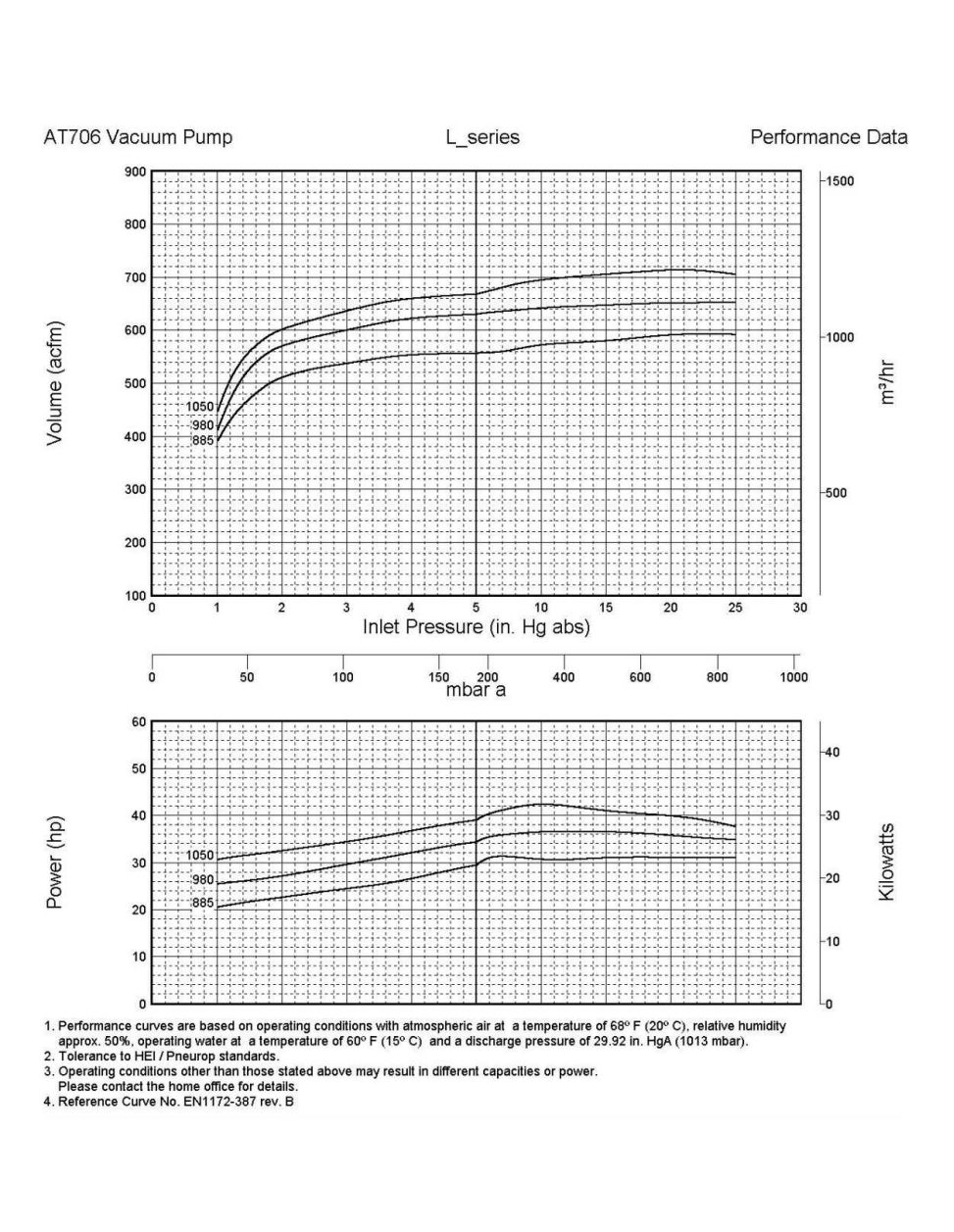

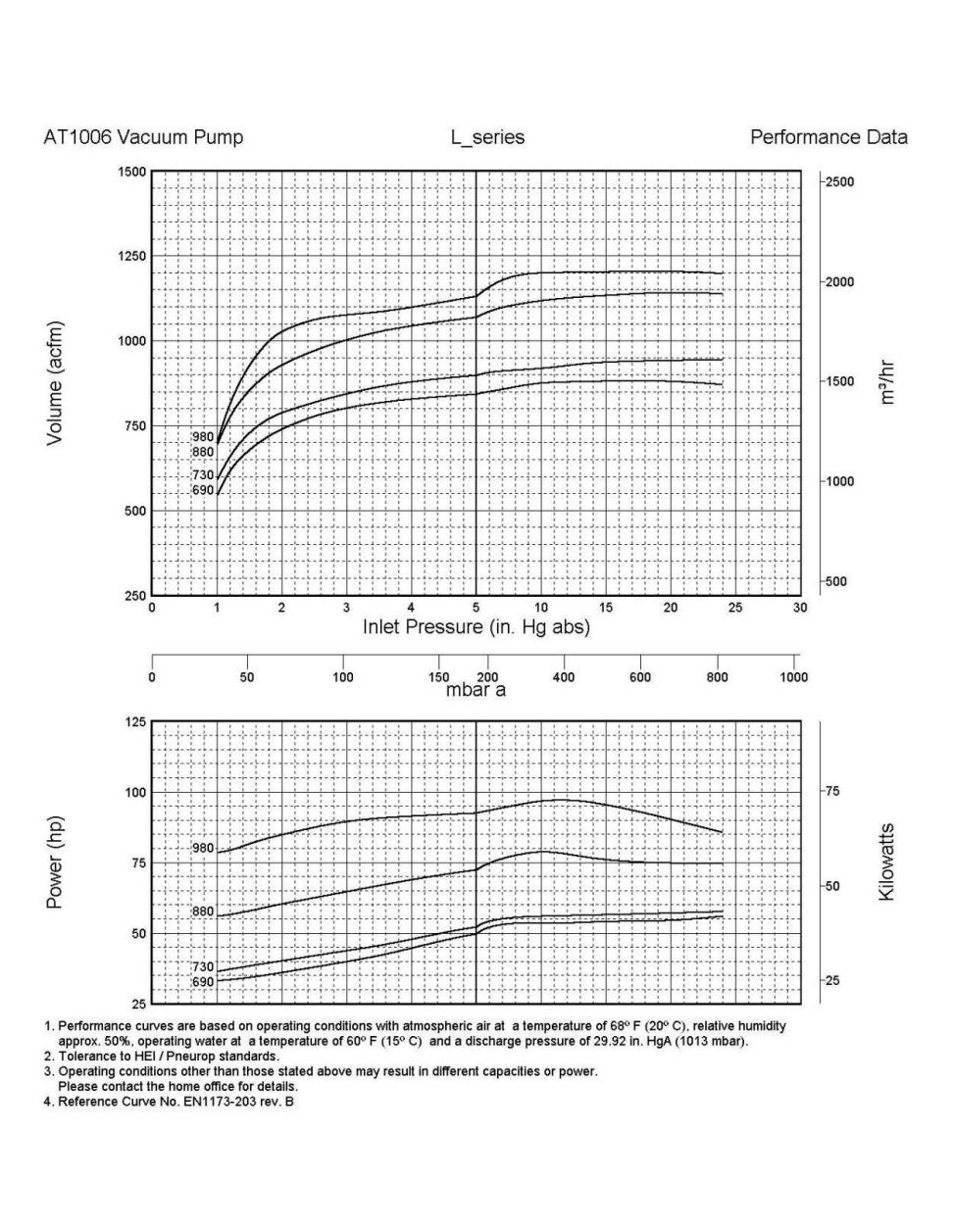

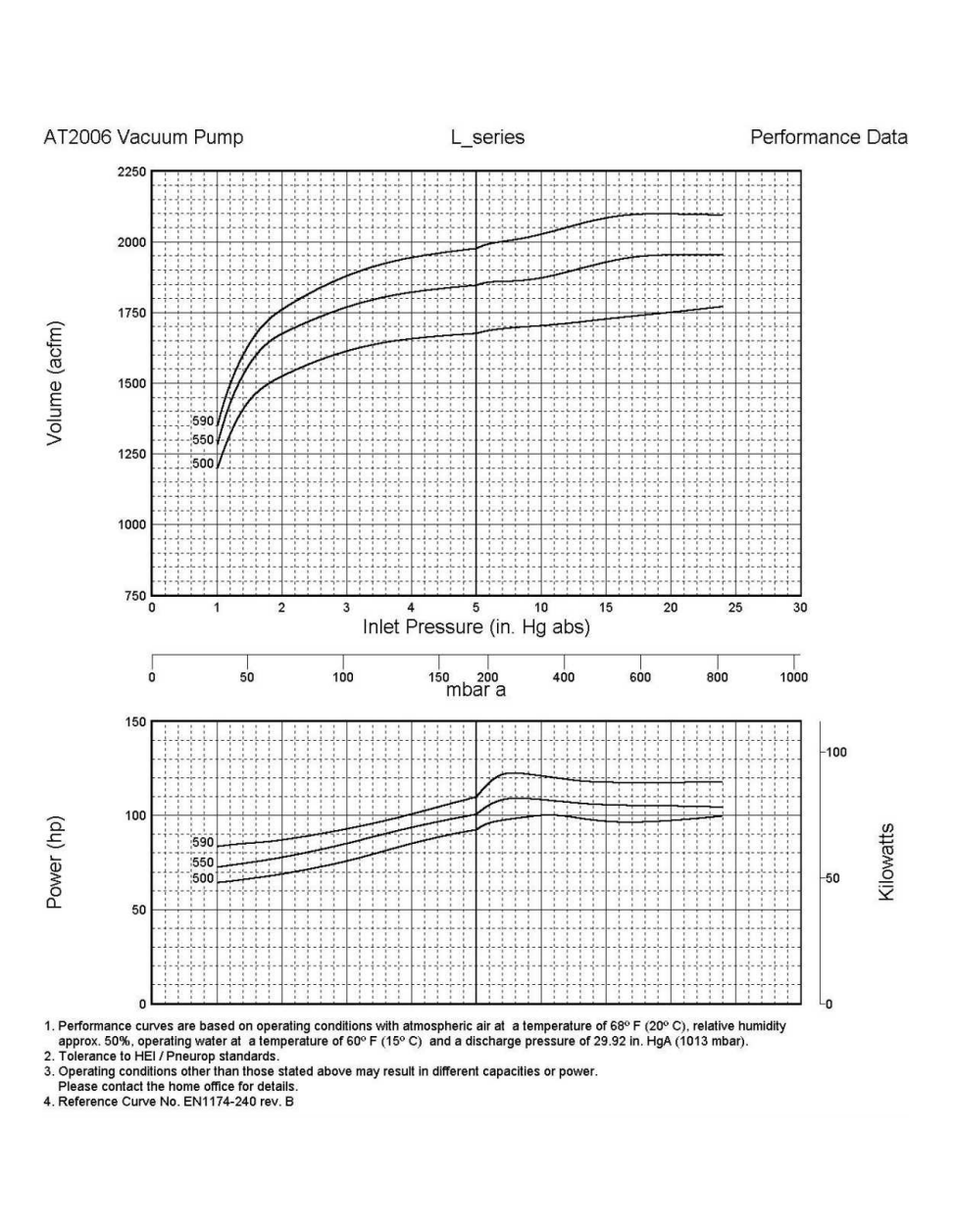

Technical

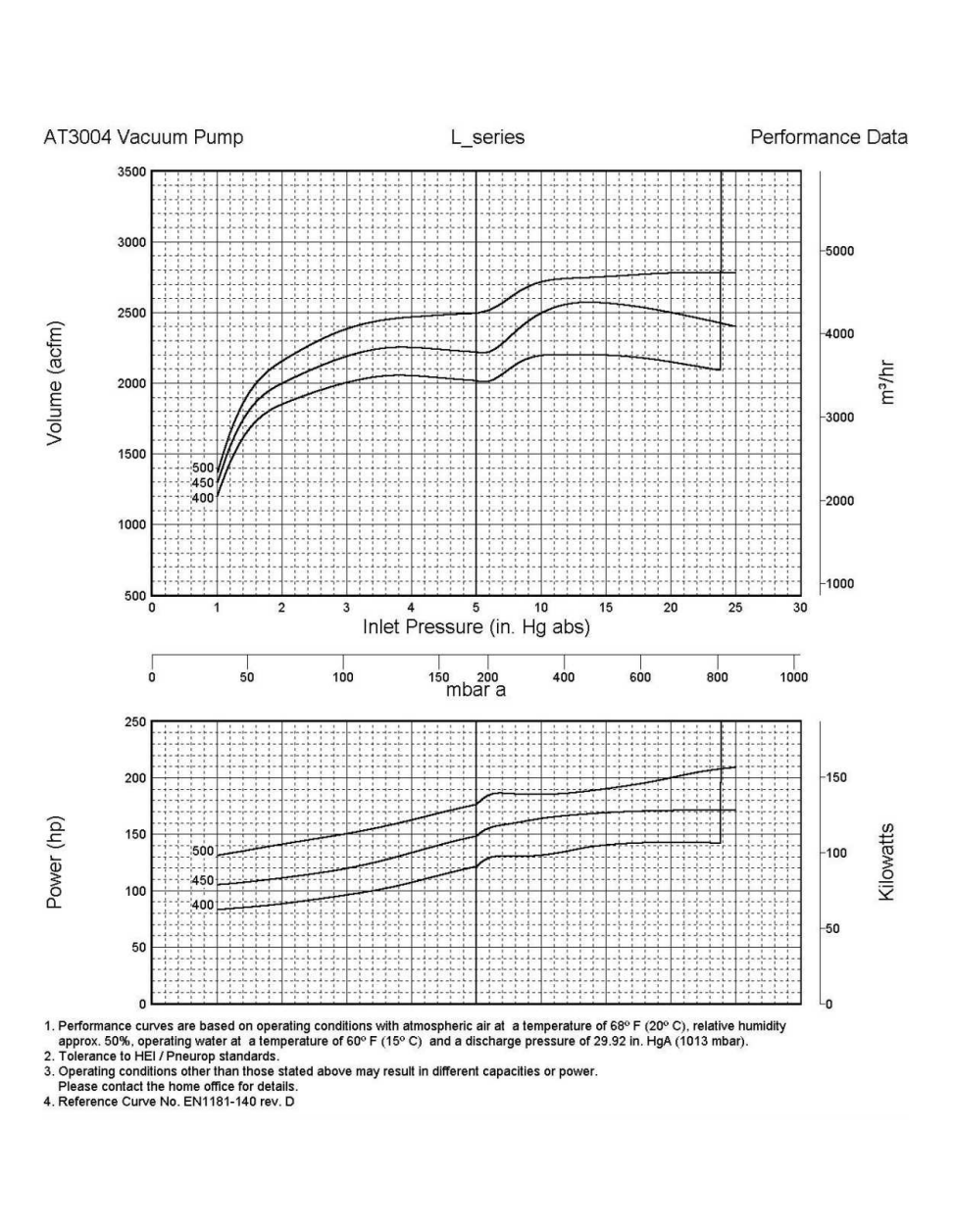

Graph:

Two-Stage Liquid Ring Vacuum Pump – Reliable High-Vacuum Solutions for Power and Industrial Applications

The NASH AT two-stage liquid ring vacuum pump series is trusted for its ability to deliver reliable, high-vacuum performance in the power industry. With a capacity range of 680 to 4,750 m³/h (400 to 2,800 ACFM), the AT series is engineered for handling saturated process gases in demanding industrial environments.

Key Features:

o Two-stage design: Ensures higher vacuum levels for demanding applications.

o Rugged and durable construction: Built for long-term use in harsh conditions.

o Wide capacity range: Covers medium to high-capacity requirements (400 to 2,800 ACFM).

o Proven reliability: Over 25 years of trusted performance in the power industry.

o Low maintenance requirements: Reduces downtime and operational costs.

Applications:

o Power generation: Reliable vacuum solutions for turbines and condensers.

o Chemical processing: Efficient for vapor recovery and gas handling.

o Environmental applications: Effective for wastewater and vapor treatment systems.

o General industrial use: Reliable for drying, forming, and coating operations.

Advantages:

o Handles saturated process gases with ease.

o Long-lasting performance for continuous operation.

o Trusted choice for industrial and power applications.

The image should depict the pump in a professional industrial or power generation setting, with visual aids highlighting its two-stage operation, rugged design, and high capacity range.

Tags :