A pressure state lower than atmospheric pressure is called a "vacuum" or a "negative pressure".

The force generated by vacuum is the adsorption force, which is the area (pressure area of the vacuum pressure between the differential pressure and the vacuum pressure. The product of the adsorption area).

Therefore, the maximum vacuum adsorption force will not exceed the force of atmospheric pressure. Changes in the atmospheric pressure can also cause changes in the adsorption force.

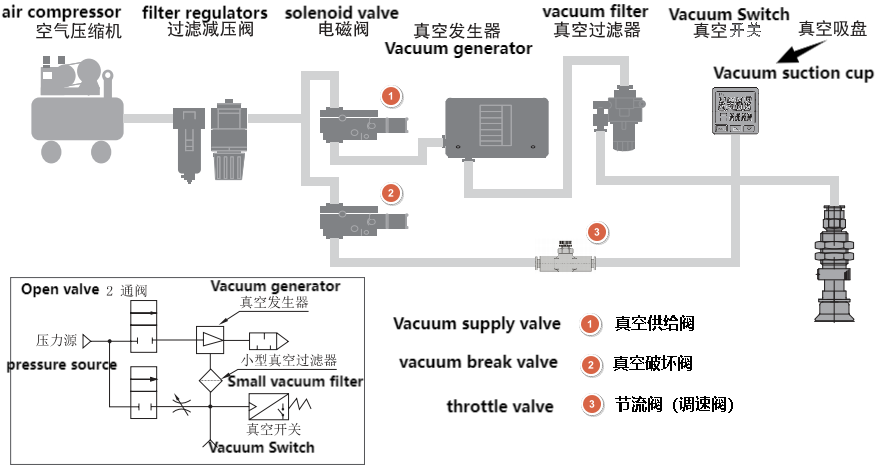

Vacuum system is a combination of components composed of a vacuum generator or vacuum pump, vacuum suction cup, vacuum pressure switch, vacuum filter, vacuum safety valve, etc. Vacuum system has the following characteristics:

· The structure of the vacuum adsorption mechanism is simple.

· The suction position does not require precise positioning.

· Suitable for workpieces with surface smoothing or curved surfaces.

· When absorbing the workpiece, the surrounding foreign bodies will be inhaled, so it is necessary to set the filter.

· To obtain a large suction force, a larger adsorption area is needed.

· Vacuum suction cup is more rubber material, easy to aging wear.

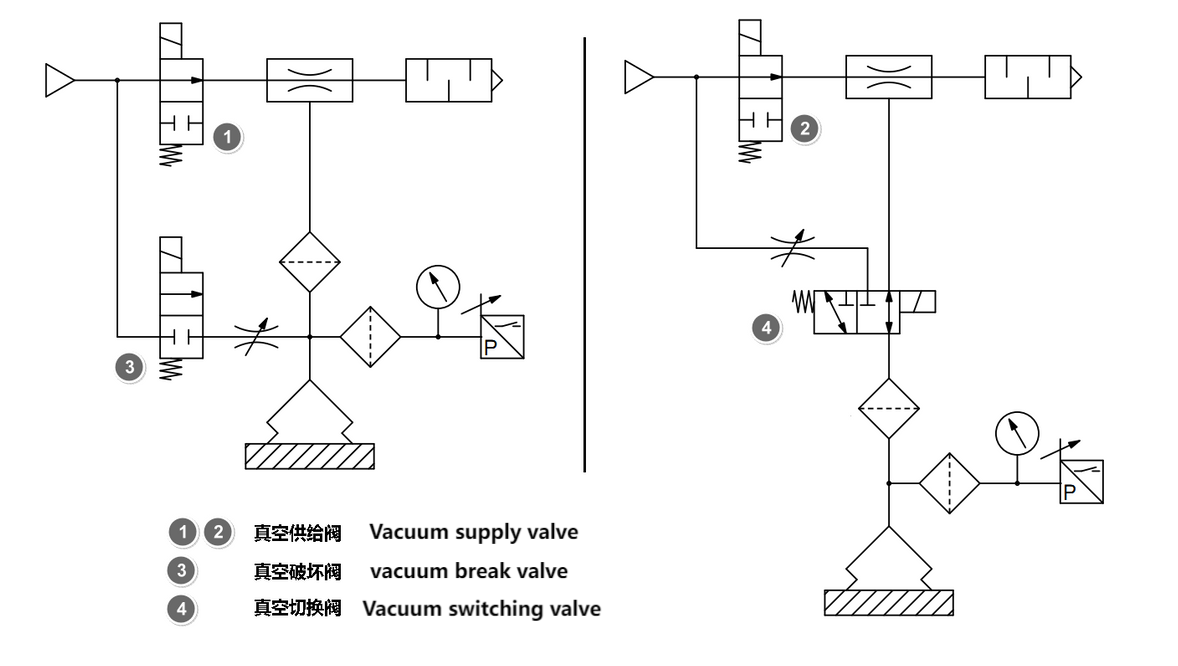

Vacuum supply valve: supply compressed air to the vacuum generator to control the disconnection of the vacuum.

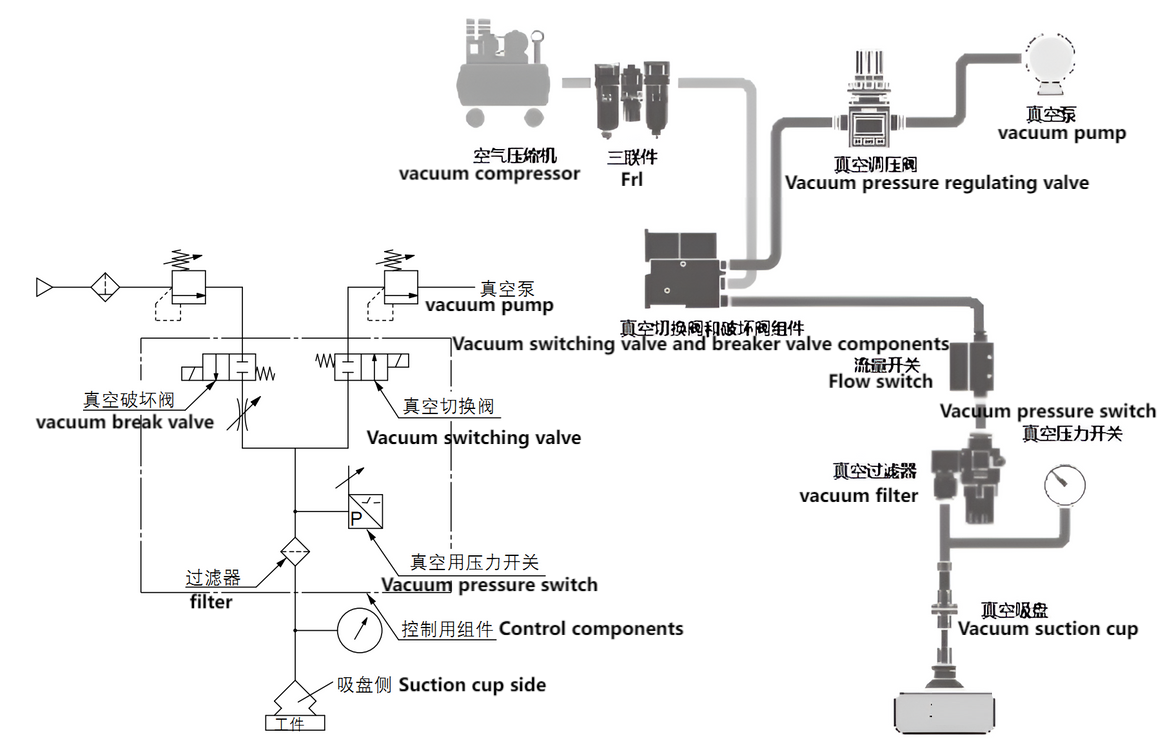

Vacuum failure valve: in order to quickly let the workpiece after the vacuum suction, control the breaking of the vacuum failure air.

throttle valve: control the damage flow rate when the workpiece is detached to control the detachment time and prevent the workpiece from being blown away.

Vacuum filter: prevent the dust around the suction cup and causing the failure of the stop valve, vacuum generator and sensor. Public number "mechanical engineering wencui", the engineer's gas station!

Vacuum pressure switch: in the vacuum suction, when reaching the fixed vacuum pressure to get the signal, as the starting point of the cylinder and whether the suction is confirmed. Two typical gas paths of vacuum system composed by vacuum generator.

Vacuum pressure regulating valve: to prevent the pulsation of the vacuum source and control the set vacuum pressure.

Vacuum switching valve: controls the switch to supply the vacuum from the vacuum pump.

Ideally, a vacuum generator with a suction cup, or a vacuum tube with a suction cup.

For a vacuum generator or vacuum pump has multiple suction cups, when one workpiece falls off, the vacuum pressure drops and other workpieces will fall off. The following countermeasures can be taken:

· Use a throttle valve to reduce the suction and unsuction vacuum pressure changes.

· Each suction cup is equipped with a vacuum switch valve, which can be switched to prevent the impact of other suction cups.

· The vacuum pump system can also use the vacuum tank and the vacuum pressure reducing valve to stabilize the vacuum pressure

· The vacuum safety valve is used to limit the vacuum drop, so that the vacuum of other suction cups is not affected.

· As a power failure countermeasure, the supply valve should be open-open or with self-maintenance function.

· The suction and handling of workpieces can be confirmed by vacuum pressure switch. When absorbing heavy objects and dangerous goods, the visual confirmation should be carried out by vacuum table.

· In a harsh environment, a vacuum filter should be installed before the pressure switch, but the hole of the filter is blocked, which will affect the pressure difference between the suction part and the vacuum generator, resulting in the real suction judgment error, this must be paid attention to.

· Compared with the positive pressure with a higher pressure, the vacuum pressure is more likely to be affected by the piping resistance. In particular, the vacuum arrival time is greatly affected by the inner diameter and length of the pipe, so the small volume is selected as far as possible.